2016 Distributor Meeting of Guangzhou HEDY Intelligent Equipment Co., Ltd. was held in HEDY Building located in Guangzhou Science City on December 16th, 2015. In the afternoon of Dec. 15th, the distributors from all over China reached Guangzhou by air or by high-speed train. And in the morning of Dec. 16th, HEDY staff and distributors visited HEDY’s factory located in the HEDY Industrial Park from the hotel by coach. Covering an area of over 133,000 square meters, with building area 200,000 square meters, HEDY Industrial Park is one of the industrial parks equipped with the best facilities in China.

The sun shined brightly when they arrived at the factory of HEDY, and HEDY staff all smiled happily. A dracaena sanderiana, shaping like a tower, was put on the front desk, which symbolized that HEDY would be better and better in the future. Manager Chen of the Production Department had waited for the distributors outside the door.

And administration staff had prepared beverage and fruits for the distributors in the meeting room.

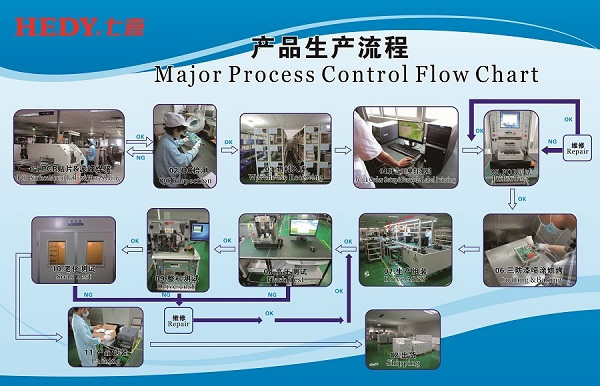

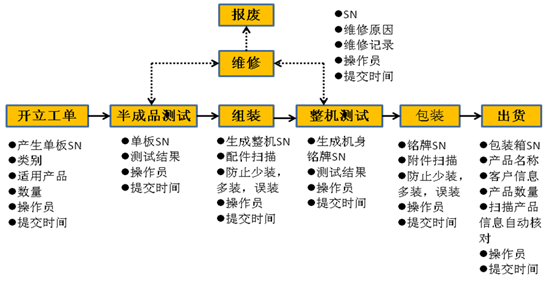

After a short break, Manager Chen led the distributor to visit the workshop. HEDY’s production is controlled by a strict management system to ensure quality, and all men should wear ESD coat and shoes cover before entering the workshop. HEDY inverters are manufactured according to a standard production process monitored by computer, consisting of 12 steps. First, materials need to go through PCB surface mount reflow and wave soldering, when done, they will come to QC test, and be put in stock if passing the test. Qualified parts will go to next step. Staff will make a work order, import data into SAC system, input barcode, and print barcodes of all electronic parts. Next step is FOB test. Before that every part will be put on a barcode, which will be scanned in every key process and the test results will be recorded into system automatically. Then products will be sprayed and baked by conformal coatings and assembly will be finished. The last stage is test.

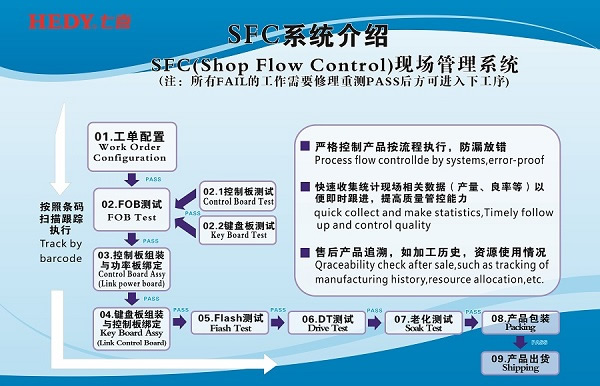

Barcodes must be scanned in every key process, and will be recorded into the database automatically by the production control system. When some process is missing, the system will alarm automatically. With the system, errors can be found immediately, problems can be solved timely and the complicated visual check can also be saved, so that fine management and high efficiency will be achieved. And this system also plays an important role in after-sale services. When parts need to be repaired or changed, only by scanning the barcode and the parameters of parts and how they are assembled will be found, which is of great for maintenance staff to repair. This system is called Shop Flow Control (SFC).

Currently, HEDY has three assembly lines, assembling 7.5KW and 37KW inverters. After assembly, inverters will go through automatic flash test, drive test, soak test. After passing all the tests, inverters will be packed and delivered.

![1506476899727925.jpg 1450429721846083[1].jpg](/upload/image/article/20170927/1506476899727925.jpg)

On the first floor of Building 1 in which HEDY is located, there is a large power inverter laboratory which is to test and debug larger power inverters and is equipped with large power motors and related loading equipment. The large power inverters produced by HEDY is tested here with motors before delivery.

![1506476917624563.jpg 1450430095779060[1].jpg](/upload/image/article/20170927/1506476917624563.jpg)

Currently, HEDY produces three series of low voltage inverters, HD71, HD700 and HD710. And next year HD800 will be produced, which has the function of close-loop vector control and supports a variety of fieldbus with communication card.

![1506476927118423.jpg 1450433044282699[1].jpg](/upload/image/article/20170927/1506476927118423.jpg)

After visiting HEDY factory, in the afternoon, the distributors returned HEDY Building located in Guangzhou Science City. Mr. Yi Xianzhong, the president of HEDY Group made a speech to them. Mr. Yi shared his experiences of selling imported inverters 20 years ago and how he made it. And he was confident in HEDY inverter for its quality and technology. To make HEDY inverter a China-made high quality product, Mr. Yi has invested 120 million yuan since 2010, setting up R&D center in Britain, and hiring experts from famous inverter enterprises like Emerson with high salary. And HEDY inverter has passed UL certification and CE certification to enter American and European markets. Mr. Yi introduced that some certified products may be different from the actually produced products, but it is unlikely for these products to get a UL certification. For UL certification personnel would do on-site check for at least four times annually. Generally, they inform the factory only when they get to the factory gate and they must reach the production shop in 15 minutes and do the check. Therefore, in daily production HEDY keeps high standard in mind, which is required not only by UL certification, but HEDY itself to create high-quality inverters. In the meeting, the distributors also acknowledged that the quality of HEDY inverters was indeed better than general domestic inverters.

![1506476939506656.jpg 1450424892263703[1].jpg](/upload/image/article/20170927/1506476939506656.jpg)

Next, Mr. Li, General Manager of HEDY, introduced 2016 HEDY business planning to the distributors. HEDY will launch servo and HD800 high-quality closed-loop vector inverter and enter some industry markets in 2016.

![1506476948701418.jpg 1450432768577293[1].jpg](/upload/image/article/20170927/1506476948701418.jpg)

And then, the staff of Sales Department and Customer Service Department talked about HEDY’s distribution policy and product characteristics in detail.

![1506476958485140.jpg 1450432842735269[1].jpg](/upload/image/article/20170927/1506476958485140.jpg)

![1506476968469218.jpg 1450432902757612[1].jpg](/upload/image/article/20170927/1506476968469218.jpg)

The meeting lasting for a day is compact and rich in content. The visit to HEDY’s factory, and the introductions by Mr. Yi, Mr. Li and other staff of HEDY made the distributors understand HEDY fully, trust HEDY more. And with good hope to 2016, on 18:00 p.m., HEDY 2016 Distributor Meeting ended successfully.

![1506476978139724.jpg 1450430625633874[1].jpg](/upload/image/article/20170927/1506476978139724.jpg)