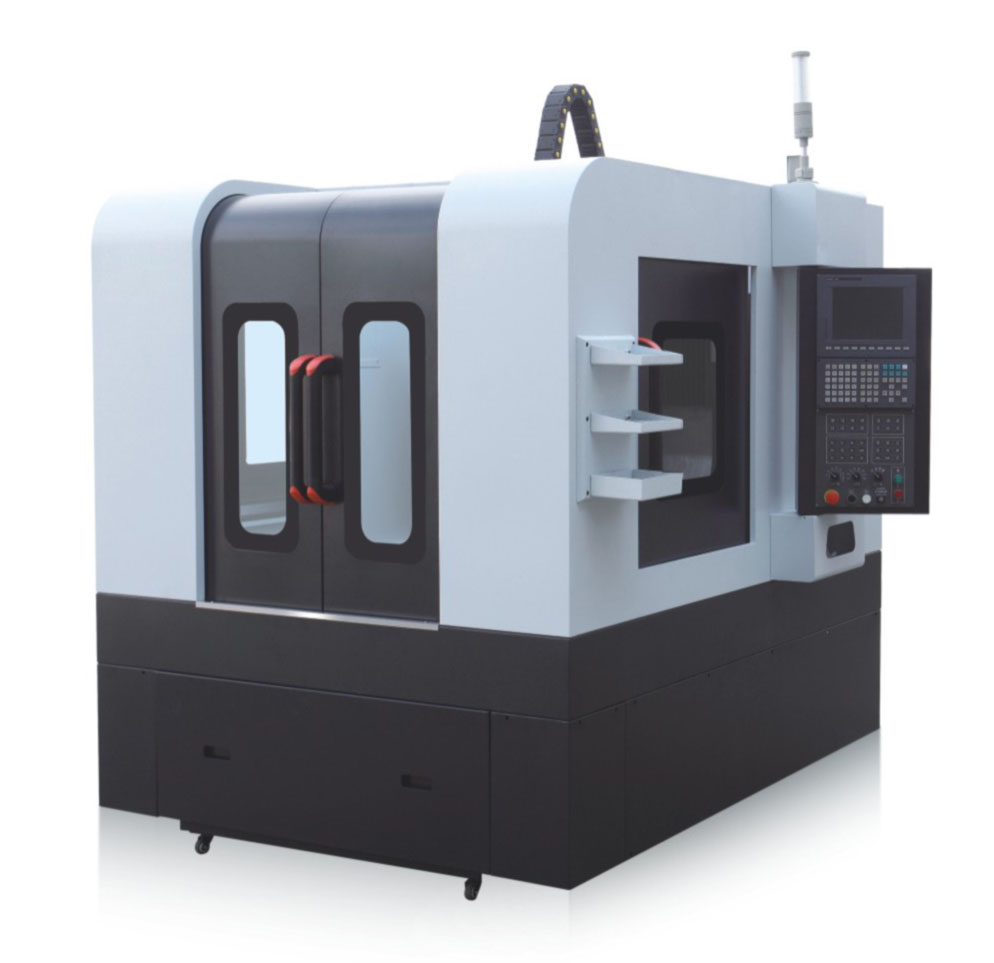

1. The spindle system is an important component of the embossing and milling machine.

(1) In the full speed range, the speed and current fluctuation is small.

(2) The low speed torque is large, which can ensure the low speed cutting.

(3) Acceleration and deceleration time shall be as short as possible.

HD700 The frequency drive has excellent motor control performance, which can meet the performance requirements of engraving and milling machine, such as wide speed regulation range, high speed stability, strong overload capacity, large low speed torque, short acceleration and deceleration time and so on. The output frequency can reach 1500Hz in high-speed mode, with strong overload capacity and stable output frequency.

2. Practical application:

Taking the 650 CNC engraving and milling machine as an example, the spindle system is required to use frequency drive to drive asynchronous AC motor to realize stepless speed change. Spindle motor uses four-pole high-speed brushless water-cooled motor, low noise, large cutting strength. The running speed is generally 0 ≤ 24000 r / min, and the corresponding frequency drive is 0~800Hz.

1. Equipment in field:

Motor model | HDK125-24Z/5.5-ER32 | |||

Rated power | Rated voltage | Rated current | Frequency | Rev |

5.5KW | 380V | 11.1A | 400—800Hz | 12000—24000rpm |

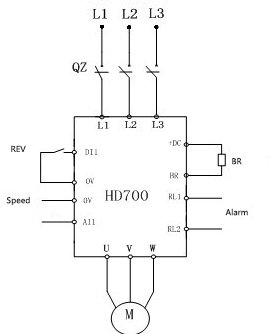

2. External cabling

2.Setting

Model: HD700-40T00550

Braking unit: 500W/100Ω

3. Parameter Setting

(1) Set the following parameters on the basis of the default settings

Code ID | Value | Description |

P00.03 | 1 | Control model:by terminal (decided by actual requirement) |

P00.04 | 3 | Frequency setting: AI1 (decided by actual requirement) |

P00.07 | 800Hz | Max frequency (decided by actual requirement) |

P00.09 | 5.0 | Accelerating time(decided by actual requirement) |

P00.10 | 5.0 | Decelerating time(decided by actual requirement) |

P00.13 | 380 | Rated voltage of motor |

P00.14 | 12.5 | Rated current of motor |

P00.15 | 800.0 | Rated frequency of motor |

P00.16 | 2400 | Rated revs of motor(under high frequency mode,2400 refer to 24000rpm) |

P21.13 | 3 | high frequency mode |

After setting the above parameters, press the "MF" key to move and observe whether the whole mechanical system is normal. If normal, enter the trial run.

Note: the above parameters are set according to the actual needs, the above table is only on-site general data. The default value of P21.13 is 0, the maximum operating frequency is 300.0Hz at P21.13 ≤ 0, the highest operating frequency is 1500Hz when P21.13 is 1, and the maximum operating frequency is 1500Hz.

(2) After setting the above parameters, P00.22 (motor torque lifting) can be adjusted according to the operation condition. The motor torque in the low frequency region can be adjusted by changing the parameter value. The larger the parameter value is, the greater the low frequency output torque of the motor is and the larger the current is. However, excessive setting may lead to overcurrent protection.

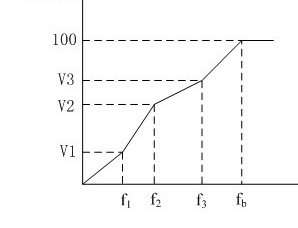

(3) Adjust V/F curve

After making the above adjustments, you can also adjust the V ≤ F curve according to the specific situation. HD700 frequency driveis a straight line by default, when P06.01 ≤ 0 (user-defined V ≤ F curve), The V ≤ F curve can be adjusted arbitrarily by P06.02~P06.07. As shown in the following figure, if the frequency and output voltage (V, F) of the three points on the V ≤ F curve are set according to the need, the output voltage of any frequency band can be properly increased or reduced according to the need, that is, the torque of the motor can be adjusted.

Code ID | description | Parameter range |

P06.01 | V/F selection | 0: V/F defined by customer 1: 2.0 law ramp 2:1.7 law ramp 3: 1.2 law ramp |

P06.02 | Frequency 3 | P06.04≤P06.02≤P13.08 |

P06.03 | Voltage 3 | P06.05≤P06.03≤100.0% |

P06.04 | Frequency 2 | P06.06≤P06.04≤P06.02 |

P06.05 | Voltage 2 | P06.07≤P06.05≤P06.03 |

P06.06 | Frequency 1 | 0.00≤P06.06≤P06.04 |

P06.07 | Voltage 1 | 0≤P06.07≤P06.05 |

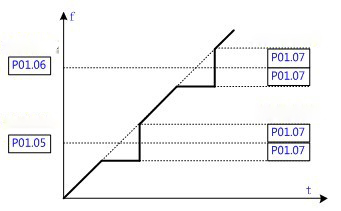

(4) If there is a resonance problem in operation, set the jump frequency when determining that the mechanical installation is normal, and skip the resonance frequency range.

HD700 frequency drivetwo jump reference (P01.05, P01.06), when the jump frequency is set to 0, the jump frequency function is prohibited. The jump frequency range parameter (P01.07) is defined as the upper and lower offset of the selected jump frequency. Therefore, the actual jump reference frequency band is twice as much as that set in the jump frequency range parameter (P01.07), and the jump reference parameter (P01.05, P01.06) defines the center point of the frequency bandWhen the given frequency rate is in the frequency band range, the lower limit of the frequency band will be the final given frequency.

The final frequency after hopping frequency filtering will be limited to the maximum operating frequency (P01.02) and the minimum operating frequency (P01.03). As shown in the following figure:

Note: during acceleration and deceleration, the output frequency of frequency drivecan cross the jump frequency, do not overlap the range of the two jump frequencies

(5) Performance

After field debugging, HD700 general frequency converter makes the spindle motor of engraving and milling machine rotate smoothly, the acceleration and deceleration time is short, and the low speed torque is large, which fully meets the requirements of process performance.