Gao Shuai Liu Qian

(Qixi Intelligent Equipment Co., Ltd., Guangzhou 510760)

Abstract: This paper introduces the working principle of modern paper machine equipment, the characteristics of production line electrical control system. To seven hi converter HD700 as the drive device to PLC for the control of the host, to achieve PLC and HD700 inverter communication, paper machine speed control, load distribution control and other functions. In the paper machine variable frequency drive system, Qixi inverter program has achieved good stability and control accuracy, better meet the needs of paper machine production line.

Key words: HD700; paper machine; variable frequency drive

The application of HEDY drive in the inverter system of paper machine

GAO Shuai LIU Qian

(Guangzhou HEDY Intelligent Equipment Co., Ltd,Guangzhou 510760)

Abstract: The working principle of paper machine equipment and the character of the electric control system of paper machine is introduced.PLC is master,HD700 is slave, the function of the communication with PLC and HD700 drive,speed control paper machine,load distribution control are realized.In the inverter system of paper machine,HD700 drive get stability and control precision,which can satisfy the production line of paper machine.

Keywords:HD700 drive;paper machine;inverter;

0 Introduction

The paper industry is an important industry closely related to the development of the national economy. It involves forestry, agriculture, machinery manufacturing, chemical industry, electrical automation, transportation, environmental protection and other industries. And now most of the papermaking enterprises to use more than one DC motor drive the drive shaft drive, can be stepless speed, but because of the existence of carbon brush to maintain a lot of trouble. With the development of AC variable frequency control system and communication technology, AC variable frequency drive system is more and more widely used in the new paper machine, wide speed range, good speed performance, energy saving and easy operation. Modern paper machine system using the host computer, PLC, inverter AC motor system, complete the paper machine monitoring, operation and production management.

The composition and principle of papermaking machinery and equipment

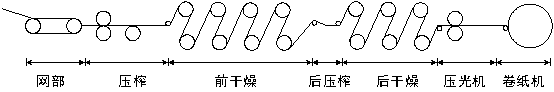

Papermaking machinery and equipment from raw materials equipment, pulping equipment, paper machine composition. One of the most central part of the paper machine, paper machine is formed in accordance with the order of the paper into the network, press, before drying, after pressing, after drying, calendering machine, reel and so on. The process is the outflow of pulp pulp pulp in the network of dehydration molding, in the press Department to compress the paper layer evenly, after drying before drying, and then into the press after the glue, and then dry drying treatment, and then use the pressure The light machine makes the paper smooth and finally forms the mother roll through the reel. Papermaking process flow chart shown in Figure 1:

2 paper machine electrical system demand analysis

2.1 paper machine automation control control requirements

a. Start requirements:

Paper machine in the transmission inertia of the larger parts, such as dryer, need to start a smooth start to avoid damage to the mechanical pumping.

b. Speed requirements:

Paper machine from the pulp to the paper, need to go through pressure spray sizing, pressing, drying, calendering and winding and other parts, is a multi-unit speed coordination control system, the speed between the various departments have a more rigorous speed Proportional relationship, otherwise it will cause broken paper or excessive relaxation, affecting the physical indicators of paper, and can not stabilize the quantitative control of the paper, affecting product quality. So the paper machine must have a higher precision of the stability of the performance.

c. Division speed requirements:

Paper on the paper by the role of traction in the net and the press Department of longitudinal elongation in the dry part of the longitudinal extension, when the paper water content decreased, the paper to reduce the longitudinal elongation deformation, the paper into the calender and roll When the paper machine is pulled, the paper is pulled and stretched so that the speed of the individual parts is different throughout the paper machine production line, which keeps the web tension. At the same time, the speed of each part of the machine must be adjustable. This prevents the paper from slipping or overtaking and breaking the paper. As the paper machine without frequent start, and the process requirements of the variable range is not large, so the speed of paper machine is the main goal of automatic control.

2.2 paper machine electrical control difficult

a. Paper machine speed control:

As the division of the production process of the paper, according to the papermaking process requirements, to maintain the latter level of tension is slightly larger than the previous level, the need for sub-line speed ratio of coordinated control, high precision and reliable to maintain this ratio factor To ensure product yield, quality. At the same time, the ratio of the speed ratio of the paper machine should be changed in the speed or stop after the restart to continue, without re-adjustment. Each part of the independent control, and has a sensitive micro-rise, slightly down and tightening and other regulatory functions, easy to adjust the operation and the difference between the front and back, to avoid the paper during the transfer process of excessive relaxation and tension broken paper phenomenon.

b. Master-slave load distribution control:

In the papermaking transmission control in a number of transmission points to drive a network or a number of transmission objects, mutual pressure to synthesize a certain moment and the synchronous operation of the situation, so that the associated transmission motor according to their own configuration in proportion to reasonable commitment to power output, Load distribution control form, if the load distribution adjustment is not good, will cause the entire load loop drive point load imbalance, wire speed is not synchronized, can not run normally.

System control scheme of seven - hi converter

3.1 characteristics of the seven hi converter

a. A full range of products through the United States UL certification, product stability and reliability.

b.5.5KW and above power standard DC reactor, reduce the current pulse value, improve the input power factor.

c. perfect protection, system stability, high reliability, built-in EMC filter.

d. ultra-low noise, carrier frequency can be adjustable in the 1K-15K.

e.IGBT Junction temperature model design and unique structural design, better adapt to the outside world of high temperature and humidity environment.

3.2 Seven hi converter system design

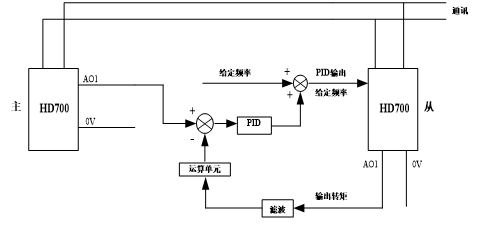

According to the paper machine on the motor drive system requirements for the system to prepare the paper machine speed of the special inverter. In the system, the re-pressure of the network as the main drive, vacuum press auxiliary drive. The main drive uses the basic speed control mode, from the transmission using load distribution control. In the slave control, the internal PID correction frequency is used for the main frequency of the inverter, and the torque output from the main drive is taken as the PID set value of the slave, and the torque output from the drive is filtered as the PID feedback value. In order to improve the control accuracy, you can adjust the PID to give the amount of feedback and the gain, such as 200%. This ensures the control accuracy, improve the stability of the system, the program shown in Figure 2:

3.3 Improve the performance of the paper machine system after applying the hixi converter

a. As a result of the hi flow overvoltage, overvoltage, overheating, undervoltage and other protective measures can effectively protect the motor, the equipment failure rate is low;

b. After the frequency control, the motor starts with a soft start to reduce the impact on the grid and equipment;

c. After the seven-hi converter system transformation program, improve the motor speed control accuracy, the speed is more smooth and stable, greatly improving the stability of the system;

d. After using the inverter, you can automatically control the drying system pressure and pulp flow, improve system efficiency;

e. After the system transformation program, the low frequency torque is large, the response is fast, the running speed precision is high and the fluctuation is small.

f. The flow signal of the flow controller signal and the drying system is output to the system controller through the analog signal of the hixi inverter to adjust the flow rate of the pulp and the drying pressure of the drying system. The operation is safe and convenient.

4 Conclusion

The conversion scheme of the variable frequency drive control system of the papermaking machine satisfies the master and slave load distribution control and speed control requirements of the papermaking machine electrical control system, which improves the reliability and stability of the system. In the paper mill has been widely used, and was unanimously approved.

references

[1] Huang Xuan, Sa Ji Ming. Paper machine AC variable frequency speed control system [J]. Beijing: China Paper, 2004.24-37.

[2] Wang Zhijun, Zhang Chi. Paper machine load distribution causes and control [J]. Beijing: China Paper, 2006.101-102.

[3] Zhang Chi. Based on PROFIBUS field bus paper machine electronic control system design [J]. Beijing: Computing Technology and Automation, 2009.28-30.